Cathodic Protection

K.C. Ltd

K.C. Ltd, established 1986, has devoted itself to design and produce corrosion protection, anti-fouling and such relevant equipments.

K.C. Ltd has numerous supply references to worldwide well-known shipping and shipbuilding companies. Their systems are installed on several thousand vessels.

K.C. Ltd delivers outstanding quality using specialized production management system and accumulated production know-how.

Main Products:

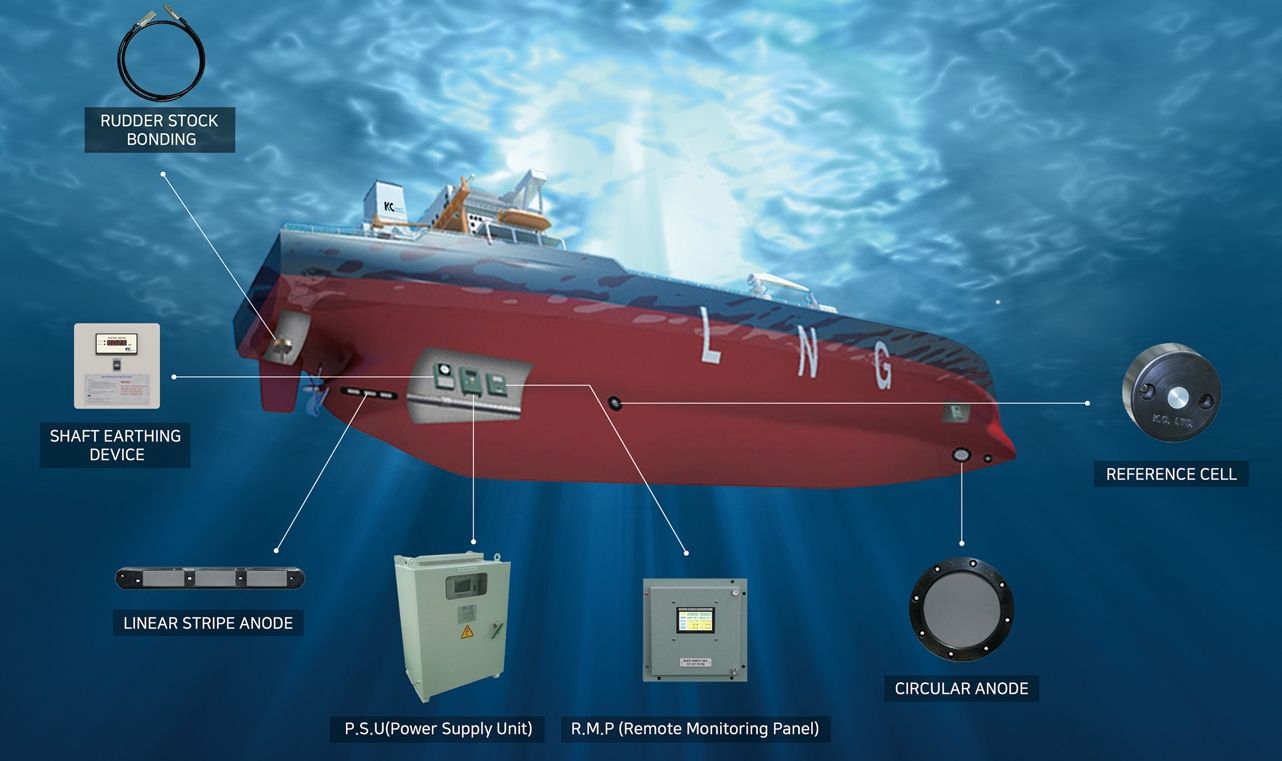

I.C.C.P. System CATHSYS Ⓡ:

CATHSYSⓇ Impressed Current Cathodic Protection (I.C.C.P.) system has been designed based on ship’s total wetted surface area of hull (including rudder / propeller) and mean current density.

In order to keep ship’s hull plate from corroding excellent anti-corrosion paints are applied with its proper thickness on the steel plate. However, whatever excellent corrosion material may be adopted it is impossible to keep hull plate perfect like new building ships till next dry dock under severe seawater. So it becomes necessary to provide corrosion protective device when ship’s hull paint is partly damaged. The electric potential of ship’s steel hull plate varies and reference cell as sensing unit catches up it well, which is based on full automatic control system without any additional try for ship’s engineers to control. When system starts there is no need of any sacrificial anodes around hull plate and shipowners can save costs for renewal of sacrificial anodes to be carried out every vessel’s dry docks.

The most efficiently protective current is automatically controlled and dissipated through anodes for the optimum potential ceaselessly measured by reference cells, which is world common technical knowledge in the field of impressed current system. Apart from the full AUTO mode control K.C. Ltd‘s sophisticated system can work on MANUAL mode which can force protective current as operators want to set. To maintain a good system for hull protection it’s necessary to check all the readings on log sheet. So K.C. Ltd regularly receives monthly log sheet from superintendents or ship’s engineers by fax or e-mail and K.C. Ltd does carry out free professional system diagnosis and report to confirm if the system works well or not.

K.C. Ltd‘s ICCP System is well known to the worldwide clients on following features.

- Auto/Manual mode

- 4.3” TFT Touch screen LCD display

- Data download is applicable through USB memory

- Easy and convenient operation by touch screen

- Data communication and alarm signal can be connected to ship’s AMS

- Simple installation to all kinds of new building as well as retrofitting ships

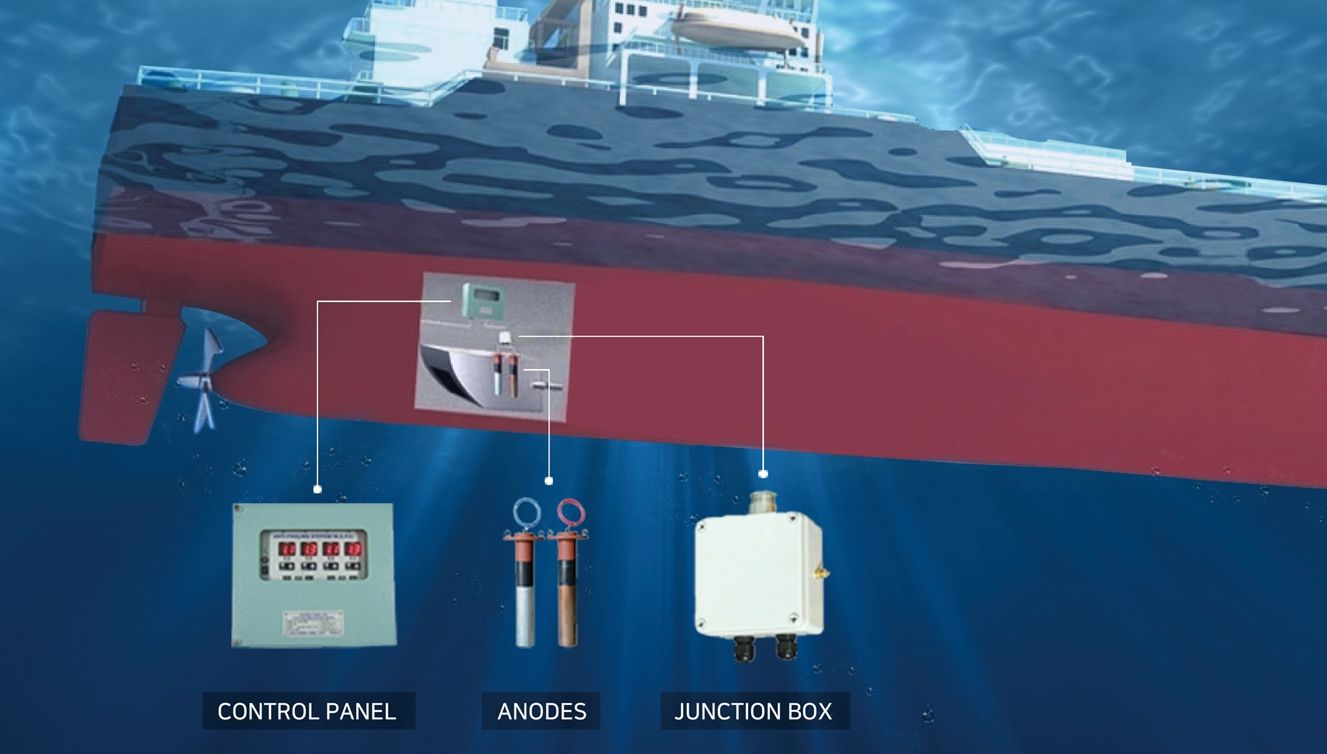

Anti-fouling System (M.G.P.S.-Marine Growth Preventing System):

ANFOSYS Ⓡ Anti-fouling system (M.G.P.S.) has been designed based on the ship’s flow rate, lifetime and dosing rate (ppb) to kill marine bio-fouling and to suppress fouling corrosion in seawater pipe work effectively. The Cu anode produces copper ions to prevent marine growth and the Al / Fe anode produces anti-corrosive layer to suppress corrosion. The anodes between Cu-Al and Cu-Fe are normally adopted according to the material of pipeline as below:

- Cu-Al anode: Steel pipeline

- Cu-Fe anode: Non-steel (Cu-Ni) pipeline

K.C. Ltd‘s Anti-fouling System is well known to the worldwide clients on following features.

- Capable of auto current change acc to 2 or 3-step flow operation

- Touch screen controller

- Low installation/maintenance costs and safe

- Environment-friendly with normal 2ppb (parts per billion) dosing rate of copper ion

- Very convenient operation on easy and sophisticated controller

- Data communication and alarm signal can be connected to ship’s AMS

- Simple installation to all kinds of new building as well as retrofitting ships

There are three choices of typical installation of anodes.

The first method is to install anodes in sea-chest and the second is on strainer and the third is in a separate anode treatment tank. There are also merit and demerit on these three different installation i.e. the anodes can be renewed/ checked only while vessel is in dry dock in case anodes are installed in sea chest. Also the anodes are free from any renewal/ maintenance/ inspection even while vessel is afloat in case anodes are installed in strainer but the sea chest and inlet pipe up to filter are not protected with the strainer installation, then they are regularly cleaned during vessel’s dry docking.

So for the efficient control from the sea chest and easy maintenance of anode the anode treatment tank is provided to inject ionized sea water into the sea chests as third method where system should be present.

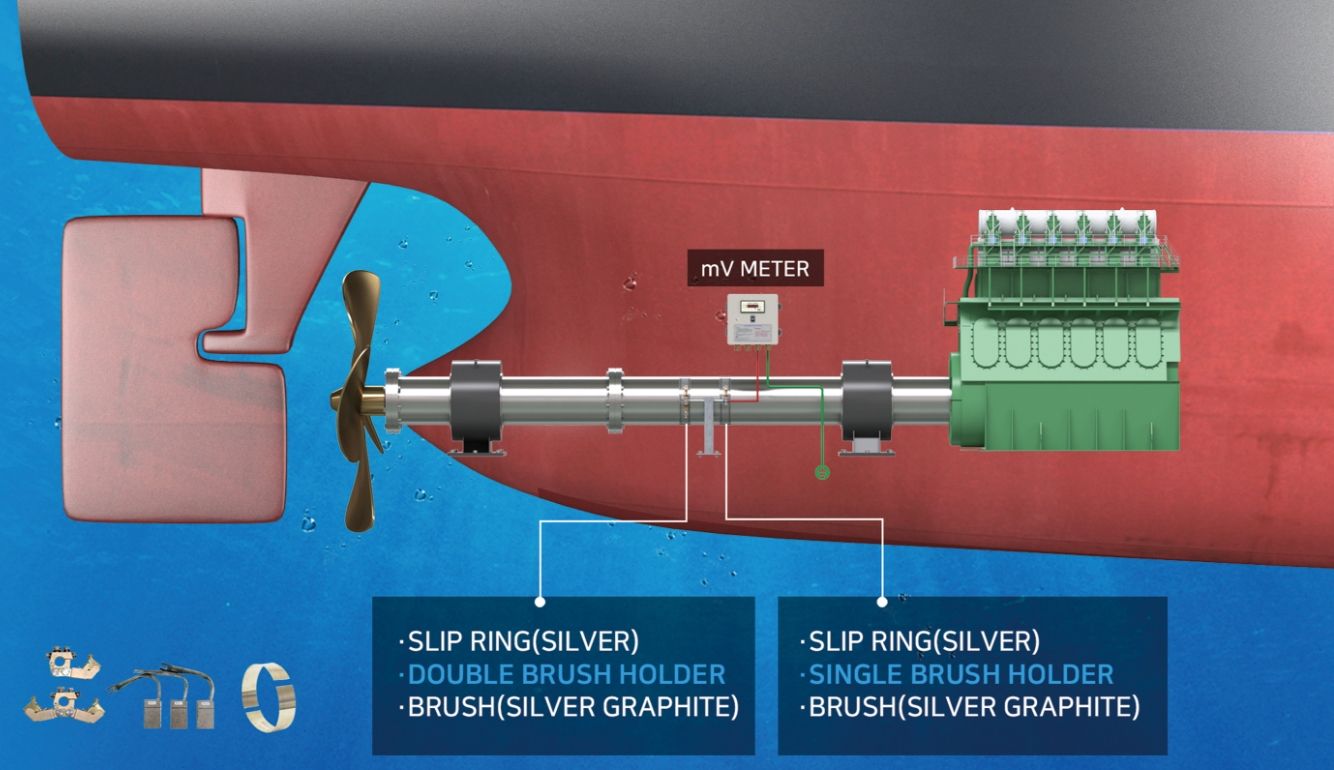

Shaft Earthing (Grounding) Device CATHSEDⓇ:

CATHSEDⓇ Shaft Earthing (Grounding) Device has been designed based on the ship’s intermediate shaft out diameter, numbers and other requirements.

A turning propeller shaft on a ship becomes electrically insulated from the hull by the lubricating oil film in the bearings and by the use of non-metallic bearing materials in the tail shaft. When the shaft is insulated in this way an electrical potential can be measured between the shaft and the hull and this can accelerate corrosion in the ship. If the ship has a system of cathodic protection, whether it is sacrificial anode or an impressed current system, the shaft insulation will prevent the propeller and the boss from receiving protection.

The electrical potential between the shaft and the hull can also cause a heavy current to flow in bearings when the oil film breaks down or is contaminated with seawater. This current can cause deep pitting of the bearing surface. Excessive wear on the shaft bearings can often be traced to this cause.

Now in addition it’s necessary to reduce the spark erosion causing the excessive wear on main engine metal bearings and this shaft earthing is the most appropriate method. All the troubles can be avoided and cathodic protection can be extended to the propeller if the shaft is properly earthed with a propeller shaft slip ring. The effectiveness of the shaft earthing system should ensure a maximum contact resistance of no greater than 0.001 ohms for a water filled bearing and 0.01 ohms for an oil filled bearing on millivolt meter.

K.C. LTD.‘s own tests indicate that high silver content brushes running on a silver track have repeatable low conductivity that can maintain these limits and ensure a low resistance contact is maintained even under dirty conditions. The shaft earthing assembly comprises a pair of high silver content / graphite compound brushes mounted in balanced brush holder, running on a copper slip ring with solid silver inlay track. Each brush holder has an adjustable spring tensioner which is supplied preset to the minimum, and results in a pressure of 225g/cm2. With this arrangement our high quality brush is in excess of one year life.

Brushes for shaft earthing device get worn down by mechanic friction on slip ring for the drain of spark inside main engine and high electric potential from stern bearing/propeller. The readings of earthing are checked through mV meter which should be maintained below a level.

K.C. LTD. produces high quality silver graphite brush and good earthing silver slip rings for longer life. Our slip ring and brush on silver material are always strong enough to endure any tough conditions.

K.C. LTD‘s Shaft Earthing Device is well known to the worldwide clients on following features.

- Very compact and light

- Fulfill the MAN Diesel’s requirements

- Applicable both current (Amp) and voltage (mV) readings

- Data communication and alarm signal can be connected to ship’s AMS

- Simple installation to all kinds of new building as well as retrofitting ships

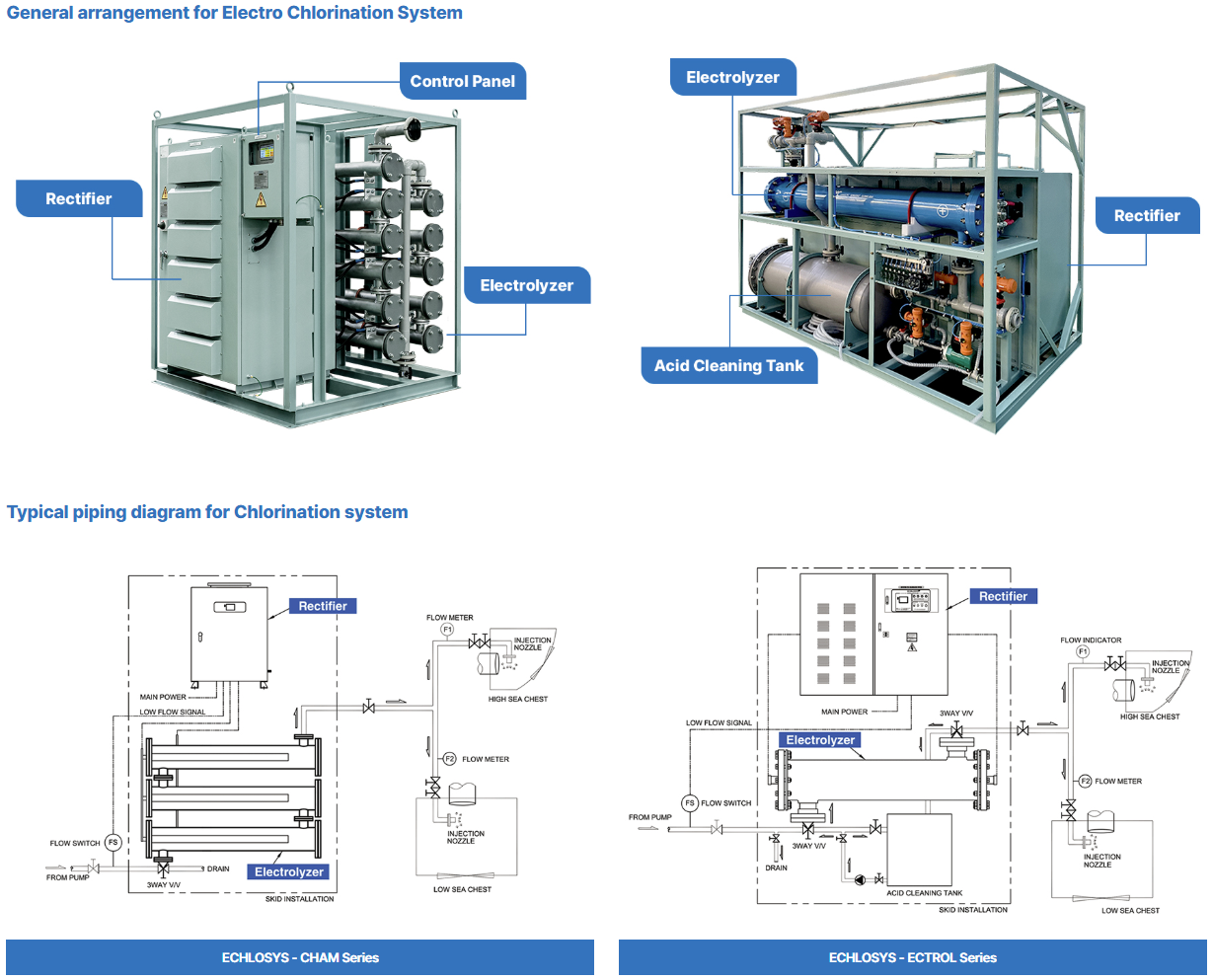

Electro Chlorination System ECHLOSYS

This system is designed to prevent the adhesion of marine growths to the internal pipe line of ships through the chemical reaction of chlorine compounds

which are produced through the electrolyzation of sea water.

First, the sea water taken out of the outlet of one of the common sea water pumps or the pump for exclusive use in MGPS is led into the Generating Chamber,

in which the sea water is electrolyzed with specially designed electrodes. Then the sea water containing chlorine compounds is injected into scoop or sea chests

through the nozzles to mix with the sea water sucked in from outside of the ship, thus preventing marine growths from adhering to the interior of the ship's sea

water line including sea chest, piping and heat exchanger.

Components

Installation

Installation requirements are limited to adequate amounts of seawater, electrical power and space. Seawater should be available through a 2"(50A) nominal

pipe at sufficient pressure and a discharge line 2"(50A), which leads to the point to be chlorinated. Seawater should be a salinity of approximately 20 to 40

ohm-cm which is the approximately consistency of sea or coastal salt water.

The input lines may be of any suitable sea water resistant material, but the output lines should be of Saran-lined steel, PVC or other corrosion resistant

material.

Operation

Chlorine Generator is designed for constant unattended operation. The Power Supply is of a constant current type, which will provide constant Chlorine Output

under changing water conductivity; thus eliminating tidal or temperature induced variances. It is equipped with safety features, which will trip the Output

circuits in case of malfunction.

Maintenance and Service

There are service and maintenance procedures presented in each of our Manuals. However, the equipment has no moving parts and should require for little or

no maintenance.

The renewal of Ti anodes will be required periodically and can be accomplished with a minimum of down time if the procedures in this manual are followed.