Deck Machinery and Steering Gear

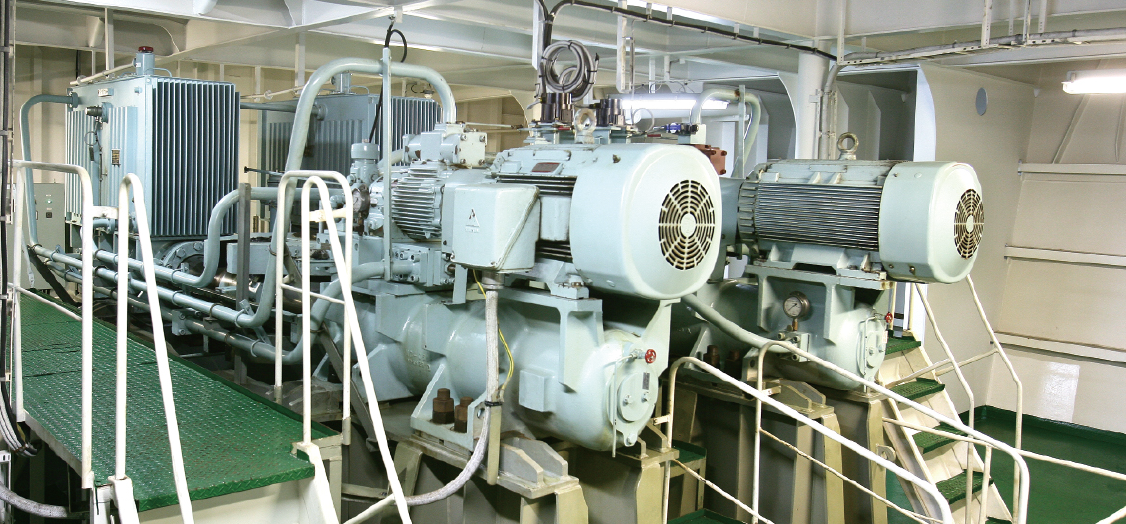

Yoowon Industries Co. Ltd., headquartered in Busan, South Korea, is a renowned manufacturer combining decades of expertise and advanced technology in the

design and production of essential marine equipment, from steering gears to deck machinery.

- Founded in 1977 as a specialized producer of hydraulic equipment and steering systems.

- In 1993, entered a technical partnership with Mitsubishi Heavy Industries, strengthening its position as a leader in steering systems for large vessels.

- By 2001, Yoowon developed the world’s most powerful steering gear with a capacity of 1,000 T-M, while expanding its cooperation with Mitsubishi to

include fin stabilizers.

Steering Gear

Yoowon designs and manufactures various types of steering gear tailored to all types of vessels:

- Models include ram type, piston type, and rotary vane type, including specialized solutions for VLCCs (Very Large Crude Carriers), offering maximum

torque capacities up to 1,021 ton-m and 45° rudder rotation. - All systems comply with major classification societies, including ABS, DNV, LR, GL, BV, KR, and meet international standards such as ASME U, PP, ISO

9001, ISO 14001.

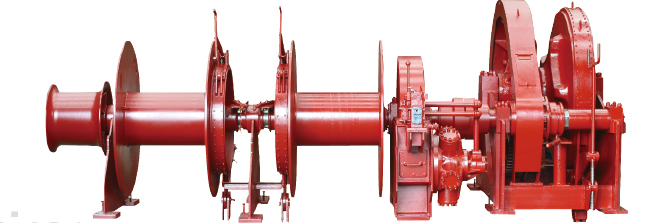

Deck Machinery

Yoowon provides a comprehensive range of deck equipment engineered for operational efficiency and simplified maintenance:

- Production includes windlasses, mooring winches, towing winches, and capstans, available in both electric and electro-hydraulic configurations, as well

as cargo and special-purpose winches for both marine and industrial applications.

Global Reach and Technical Support

- Since its partnership with Mitsubishi in 1993, Yoowon has successfully delivered and installed over 4,000 units worldwide.

- With manufacturing facilities in both South Korea and China, Yoowon combines innovation, reliable quality, and responsive global service coverage.

Window Wiper

Jung-A Marine Co., Ltd.

Jung-A Marine Co., Ltd., established in 1987 is a professional manufacturer of marine equipments and offshore structures such as accommodation ladder, wharf ladder, window wiper, CVS, davits and helidecks

Jung-A Marine Co., Ltd. provides high quality products for the worldwide shipbuilding market based on excellent technology and reliability.

Jung-A Marine Co., Ltd.‘s reasonable business, outstanding manufacturing technologies, high quality raw materials and price competiveness have resulted to become a primary business partner to the top shipbuilding companies worldwide.

Main Products:

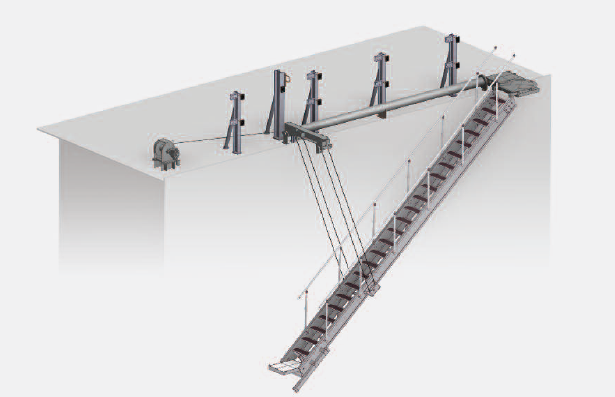

An accommodation ladder is used when the passenger get on or off the ship. This product is working by using the power plant of the electricity, air, etc... It classify the generally three types of VERTICAL STOWING TYPE, 180 TURN OVER TYPE and HORIZONTAL STOWING TYPE according to the stowing method of the ladder and they are decided by the ship ′s shape or the owner ′s request.

This product has many cases that must get the ship ′s class or the authority according to the condition of the ship′s navigation.

Accommodation Ladder:

An accommodation ladder is used when the passenger get on or off the ship. This product is working by using the power plant of the electricity, air, etc... It classify the generally three types of VERTICAL STOWING TYPE, 180 TURN OVER TYPE and HORIZONTAL STOWING TYPE according to the stowing method of the ladder and they are decided by the ship ′s shape or the owner ′s request. This product has many cases that must get the ship ′s class or the authority according to the condition of the ship′s navigation.

Three different types available:

1. VERTICAL STOWING TYPE

2. HORIZONTAL STOWING TYPE

3. TURN-OVER STOWING TYPE

| Material: | Extruded aluminum alloy and steel |

| Surface finishing: | Aluminum part to be finished with aluminum color by maker’s practice. Steel part to be hot dip galvanizwd or aluminum color coating. |

| Construction: 1) Nominal length (L): 2) Standard breadth (B): 3) Nominal inclination: 4) Winch operation: |

5 m-30 m 600 mm 55 degrees (NMD : 50 degrees) Electric or Air Source. |

1. VERTICAL STOWING TYPE

TORQUE TUBE LADDER SYSTEM

- This equipment has wire arrangement that the ladder can be stowed or turned-out at one position.

- Simple in structure and free from any torsional strain to the ladder in its stowing by menas of TORQUE TUBE connected to davit arm and upper platform.

- Ladder of 5 to 13 meters length is effective in this type. Automatically operated and stowed at vertical position.

- Either electric source or air motor is available as power source for operation.